Off the Grid - Going Solar

One of the objectives of this lifestyle is to get off the beaten path a bit more. Going off the grid. To do that we wanted to go solar.

Going off the Grid

The majority of RV’s stay in established campgrounds with “full hookups”. That is, power, water and sewer connections. It makes the RV much more like a house when you have all three. You can run air conditioners when it’s hot, microwaves for easy cooking and so on. For many people, this is camping and it’s fine for what it is. But we didn’t embark on this lifestyle to stay in a substitute for a suburban house. We wanted to stay out in places far from the crowds and much closer to nature than you find with the typical commercial campground. To do that means you give up the full hookups. The RV has fresh water and waste tanks and we can stay out for about a week before we need a re-fill on the water. Power on the other hand is a bit harder.

Most of the systems in an RV run off 12V battery power. Power hogs like air conditioners and microwaves generally need 120VAC or “shore power”. The fridge runs on propane when off grid and the furnace and water heater do as well. The water pump and all the lights run off 12V battery power. In newer RV’s all the lights are LED’s so they are very efficient. So far so good if you have enough battery capacity. So what does the average RV come installed with? You guessed it, not nearly enough. One, maybe two deep cycle “marine” batteries. If you have to run the furnace all night you’ll probably wake up to a cold RV and dead batteries.

So to spend any time out in the “boonies” you need more battery capacity. The second issue to address is you need a way to charge them back up. With shore power it’s easy. The “converter” installed in most RV’s is nothing but a battery charger and it keeps the batteries topped off continuously. Once off shore power you need another source. The first choice of many is a generator and that works well. We have a small Honda generator to serve that need. But running a generator every day for an extended period gets old. That’s what we had on the motor home and we wished for a better solution. Solar is becoming the practical answer for RV’ers that want to get off the grid. For us, it was the solution that made the most sense.

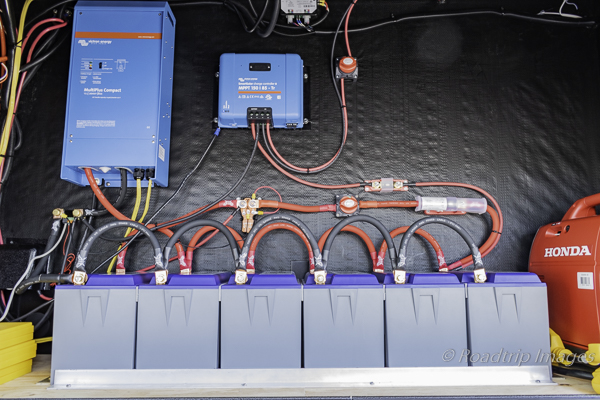

The following segments will get a little technical but stay with it. It’s not too bad. The image below shows most of the parts needed for a full system.

The Batteries

In order to go solar you need a place to store all that free energy from the sun. A battery is the logical choice. A lot of batteries if you want to survive some cloudy days. They are rated in amp-hours of capacity. So a 100 amp-hour battery can supply 100 amps for an hour before being totally discharged. Or 10 amps for 10 hours. But as I explain below, you don’t really get to use all that if you want your batteries to last.

Batteries come in several types. The typical car battery is a lead-acid “wet cell” technology. It’s been around for decades and works very well. It has a couple of drawbacks however. First it’s heavy. It’s made of lead. Second, even a deep cycle battery can only safely be discharged to 50%. Any more than that and the battery life will be shortened. Do it too many times and the battery will be ruined. So for a 100 amp-hour battery, only 50 amp-hours are usable. 6V golf cart batteries are a little more robust but the 50% discharge limit still applies. So a battery bank of lead-acid batteries was not our choice. Next best option is Absorbed Glass Matt technology or AGM for short. These are maintenance free and are still the choice for many off grid applications like on sailboats. Still very heavy but much more robust than a lead acid battery. But because of the weight, we didn’t choose them either. I wanted something better.

Lithium Iron Phosphate or LiFePO4 is a relatively new technology for deep cycle batteries that have a lot of benefits for off grid applications. First, you can discharge them down 80% and they bounce right back with a recharge. Second, they weigh significantly less than lead-acid or AGM batteries. Third, the new offerings out right now have integrated battery management systems built right into the battery case. It won’t let the battery discharge too far or too fast. It will also shut down if the battery is in an over or under temperature situation. The big drawback still for Lithium is the cost. A single 100 amp-hour battery is roughly four times the cost of an equivalent amount of usable amp-hours in a lead-acid battery. Despite the cost, this is what we chose. Over the lifetime of the batteries, the Lithiums are actually competitive since they last far longer than the lead acid batteries. Plus we saved a lot of added weight to the RV. The six batteries gives us 600 amp-hours of capacity and since we can use up to 80% of that, 480 amp-hours of useable capacity. 600 amp-hours of lead-acid batteries would only net 300 amp-hours for example. The brand we chose was Battle Born batteries out of Reno, NV. They’re made here in the USA. The folks there were super helpful with the system design and expediting parts when needed. They also supplied beefy 1/0 AWG cables to wire the batteries up with. I bought the Victron components mentioned below from them as well so they sell more than just the batteries. It’s a relatively new company and they are very customer focused. Really good folks to work with.

Solar Panels

Solar panels have been around for a long time. The technology is pretty robust and many manufacturers will warrant them for 25 years. There are two types of panel technology out there, mono-crystalline and poly-crystalline. Both refer to the type of silicon wafers used to produce the panel elements. The mono type put out a little more energy than the poly given the same area but are also a bit more expensive. I decided to go with the mono-crystalline technology for its higher efficiency.

Panels come in many sizes but 100W panels are pretty common. I chose to go with that size and used panels from Renogy Solar. They are available from Amazon and were available with Prime shipping. I went with eight panels for a total of 800 Watts. The installed panels are shown in the image at the top and below.

Charge Controllers and all the Other Stuff

Now that we have the batteries to store energy and solar panels to generate energy we need a way to get that energy in and take energy out properly. We need some controllers. The complete install is shown below. First up is the inverter/charger and is the large blue box on the left in the photo below. It charges the batteries when we’re hooked to shore power or when we hook up a generator. It’s an intelligent three stage charger that knows how to charge lithium batteries. You need that. I chose the Victron brand based on reviews and prior knowledge in the marine segment. The second function it performs is as an inverter. This takes energy out of the 12V DC battery and converts it into 120V AC that you need to run the microwave or countertop appliances like coffee pots, blenders, etc. I bought the 2000W version which means it can supply 15 amps of 120V AC or the equivalent of one household circuit. Enough for what we would use.

The second controller is the solar charge controller and is the second blue box next to the inverter. This box takes the current from the solar panels and converts it to the correct voltage to charge the batteries. They need a specific voltage for each of the three stages of charging: bulk, absorption, and float. This is also from Victron and is a MPPT controller. This stands for multiple power point technology which is the more advanced controller technology and is also more efficient than the PWM type controller.

Each solar panel puts out around 18.9 volts DC at 5.3 amps. I decided to wire them in a series-parallel combination. Two panels in series, parallel with two panels in series, etc for a total of eight panels. This gives me an operating voltage of 38 V DC which is more efficient for the MPPT controller. The combined current of four of the series combo’s is 4 x 5.3A = 21.2 amps at 38 Volts DC. The MPPT controller then steps the voltage down and the current up to what the batteries can use, around 14.4 volts. The current gets bumped up to 50+ amps DC at full sun.

The other components mounted to the back wall are disconnect switches to take the batteries and solar off line when needed for maintenance. There are also inline fuses to protect from an over current situation. On the far left is a device called a DC shunt that measures the current flow into and out of the batteries. It uses that along with the battery voltage to show the state of charge on a remote monitor panel.

One nice thing about the solar charge controller and the battery monitor is both are Bluetooth enabled so I can monitor everything from my iPhone.

Final Thoughts

As we mentioned in the previous post, we’re doing some configuring to the new rig. This is one of those and a big one. Also, as full time RV’ers, doing an install like this on the road can be a little more difficult. We’re living in the rig while I’m re-wiring things. We decided to do this while in South Dakota for our “annual” visit. Having access to the big box home improvement stores was key. As was having a campground that allowed us to make these fairly major changes.

This was a fairly complicated install. If you don’t have any experience designing and wiring a system like this, doing this as your first one would not be a good idea. Plus, some of the install deals with 120V AC circuits in the RV so unless you’re very experienced with that, get some qualified help. My intent was to de-mystify an install like this and to clarify some of the concepts. Even if you have someone else do the entire install, it helps to understand what they’re doing.

We don’t have enough time off grid with the system yet to know if this is the right capacity or not. I have room to expand if need be but I don’t think it will be necessary. We’ll be testing it pretty thoroughly in the near future as we head up into the Canadian Rockies for an extended period. Much of this will be off the grid. And after all, that’s why we did this install in the first place.

I have created a list of all the components used in the resources page. You can access that here.

As always, you can see higher resolution images on our Facebook page. Please give us a like while you’re there.

Subscribe and Get Free E-Book!

18 Comments

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed.

What does it cost to have this system done

It depends on how much you do yourself vs. hiring it out. I have roughly $8500 in parts into the system. The lithium batteries are a significant percentage of that. If you have someone do the entire install it would add substantially more to the cost for labor.

How does the solar system react when you plug into shore power? Do the solar and shore power work in unison or does shore power totally take over?

Haven’t looked into it in depth to be honest. When I’m on shore power the output of the solar charge control is zero since the batteries are in the float stage.

Gentlemen, we have found with our rig using similar Victron and Renogy equipment that the solar will take priority if you use the Hub-1 assistant, it works really slick. As your usage comes up the solar will supply what it can, if at a certain point the solar can’t keep up the multi-plus begins supplying the remaining current as needed to keep the batteries charged. Having the float voltage set point correct is also an important factor, lithium batteries maintain their voltage very well so if you set your float too low (13.2vdc for example) the solar charge controller doesn’t think the battery is in use. We ultimately found 13.6vdc for our Renogy battery works well however when in long term storage I will set the float back to 13.2vdc. Not sure what Battle Born recommends but I suspect it is something fairly similar.

Dave,

What did you do for a transfer switch? Did you use the internal bypass in the MultiPlus or install a manual switch?

Thanks,

Lee

I do it manually.

Hi Dave

Weight is for us RVers a substantial factor. Can you tell, what the weight for the whole thing is?

Thanks Manny

Looking at the major items: Lithium batteries are 31 pounds each. Victron inverter/charger is 25 pounds. Victron solar charge controller is 9.9 pounds. Renogy solar panels are 16.5 pounds each. Total weight for these items is 353 pounds. Add in for the cabling, switches, fuses, etc. Maybe 25 pounds. Total of all is probably around 378 pounds.

Thanks Dave, for your details. I was asking because I’m running pretty close to the max.

Save travels

Manny

Dave,

How did you integrate the inverter to the main electrical panel (i.e. pick certain circuits) in the coach or do you just have one or more dedicated electrical receptacles?

The output of the inverter is fed back to the distribution panel via a 15A breaker. I manually switch this. This allows me to power a variety of circuits although not all at once since I have only 2000W. Another approach is to add a sub-panel and have to inverter feed that with dedicated circuits in the RV.

Nice install, we have something similar with a 3000w multi-plus and 700w of solar feeding two charge controllers. You will love the silence and the freedom it will provide even when traveling from spot to spot it is nice to just pull over and have everything work just as if you fired up the genny or plugged in. Safe and Happy travels to you!

Great information and article. Followup question related to your April 19, 2019 response to Robert Dalga’s question: is there a chance that if you were to forget to trip the 15A 120V breaker from the inverter to the AC distribution panel before you plug into shore power, that you could damage the inverter or other AC equipment and blow the main AC breaker when you connect to shore power, or can it safely operate in parallel with shore power? Also, did you remove the original RV AC/DC converter/charger and wire your original AC and DC distribution panels from the new inverter?

Dave,

Glad you covered the battery cables and where they came from (Battle Born) in your blog. I’ve been researching how to build a system like this and that was one of my concerns was where to find cables. Ace/HomeDepot/Lowes don’t stock that type of cable. I haven’t checked solar and/or electric suppliers in my area but even if they have it, I can’t imagine it’s cheap. From the way you described it in your blog it sounds as if Battle Born supplied those cables with the six batteries at no additional cost. If that is the case, that is way cool. I didn’t know they supplied the Victron components as well. That is also cool on the customer service front. I have read from many sources that the Victron components are the gold standard…but I have also read that their customer service is seriously lacking. I have read from you and many other though that Battle Born’s customer service is top notch, so it’s nice to hear that one could get the Battle Born Customer service experience for Victron components.

There are a few questions I was hoping you might address with your install, I tried to vet them against questions you’ve answered in comments and on your Q&A video:

Specialized electrical tools and crimping technics?

In my research I have read that making the cable connections with large gauge cables and battery lugs is critical and takes some skill and special crimping tools…specifically a hydraulic crimper. I saw in your first video that you appeared to have a hydraulic crimper. I called and electrical supply to price hydraulic crimpers and they wanted $900! A bit steep for a DIYer. I didn’t see any tools listed in the link lists you provided; can you talk about the hydraulic crimpers you used, where to buy/rent and how much? In your second video you did a great job covering the MC-4 connectors and the tools you need for that. Thank you.

Conduit from Roof to the basement.

We have a GrandDesign product as well; ours is a 2015 Momentum 350M. My basement looks very similar to yours in size, layout, and equipment. Biggest difference is that because ours is a toy hauler we have the built in Onan 5500 kw generator on the same side you put your Honda genny. Cutting holes in the roof and wire runs are some of my biggest concerns in doing a project like this. You pointed out in your video that you made use of a preexisting conduit from the roof to the basement to run your solar panel wires. What was that conduit for? Do you know if that is that a common feature across different GrandDesign models or is it unique to your Solitude?

I have the same wire run concerns for the charge controller and Battery monitors. How did you run wires from the basement to the cabinet where you mounted the head units inside?

I should have mentioned up front, great videos! Thank you for posting them!

Hi Andy – The hydraulic crimper I have is from Harbor Freight. It doesn’t do the 1/0 AWG battery cables though. For that I have a hammer crimper. Kind of crude but it works. The cables I got from Battleborn were done with a hammer crimper too. For the cable run from the roof to the basement I used the existing conduit that Grand Design installed in the rig. It’s there for applications just like this or for roof mounted satellite TV, etc. I don’t know if the toy hauler series has this feature. The Solitude line does. AS far as the remote monitor mounting, I pulled the switch panel for all the lights, etc and could see that it had an open space down into the basement. It’s in the same cabinet that I mounted the monitor. I was pretty easy to run the monitor cable from the basement to the front bay where the batteries are installed. Hope that helps.

Awesome video and very similar to what we are considering, although we are wanting 6 x 200W panels and a 3000W inverter. I’m wondering if you might have a schematic for the system that you would be willing to share. What gauge of wire did you run from the roof to the charge controller? I see some that use a combiner box and then size up to a very thick cable to run through the roof. Thanks again, great video.

Sorry but I don’t have a schematic to share. I ran 10 AWG from the roof down to the charge controller. Since I run a higher voltage from the roof the cable size can be less. If all the panel were in parallel then the cable may need to be larger.